I joined Stryker Instruments in 2001 and managed the cutting accessories group for two years. I worked closely with many surgeons who were our customers and had several informal discussions. We would discuss the features they desire and the product launch roadmap. Based on this knowledge there were three key aspects that I felt that surgeon (our customers) were looking for (1) faster launch of products, (2) very high reliability and (3) significant improvement in existing products. I made it my objective to address all the three aspects without significantly increasing costs.

I came to Stryker from metal cutting and machine tool industry. During these two years I had learned that medical devices have to go through rigorous testing and documentation to satisfy FDA requirements. This rigorous testing was performed to ensure reliability; however, it was a significant burden on the company if the company wanted to launch products faster. When a product went from concept to launch, on an average five or six design versions were made before the design could be finalized. For each design version 30 to 35 prototypes were made. All these prototypes went under rigorous testing and documentation in the test lab to determine the failure modes. Custom test equipments were designed by test lab engineers and operated by test lab technicians to test prototypes. Depending on the complexity of the product within the instruments division, an iteration of prototype development and testing took three to four months. Considering five to six design versions are made, the average time needed to complete five to six design-prototype- test iterations would be approximately twenty months. There are six people in the test lab dedicated to a product: one test lab engineer, two technicians on first shift, one technician on second shift and one technician on third shift. So a product would take 20 months x 6 people/12months=10 man years of testing and approximately 180 prototypes are made for testing for five to six iterations.

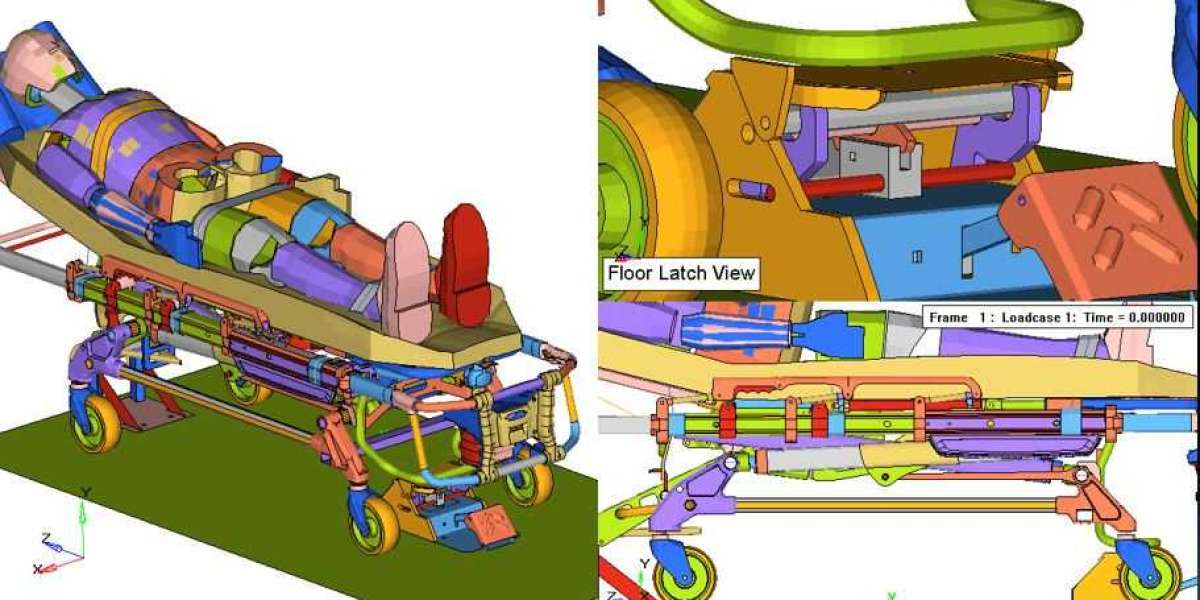

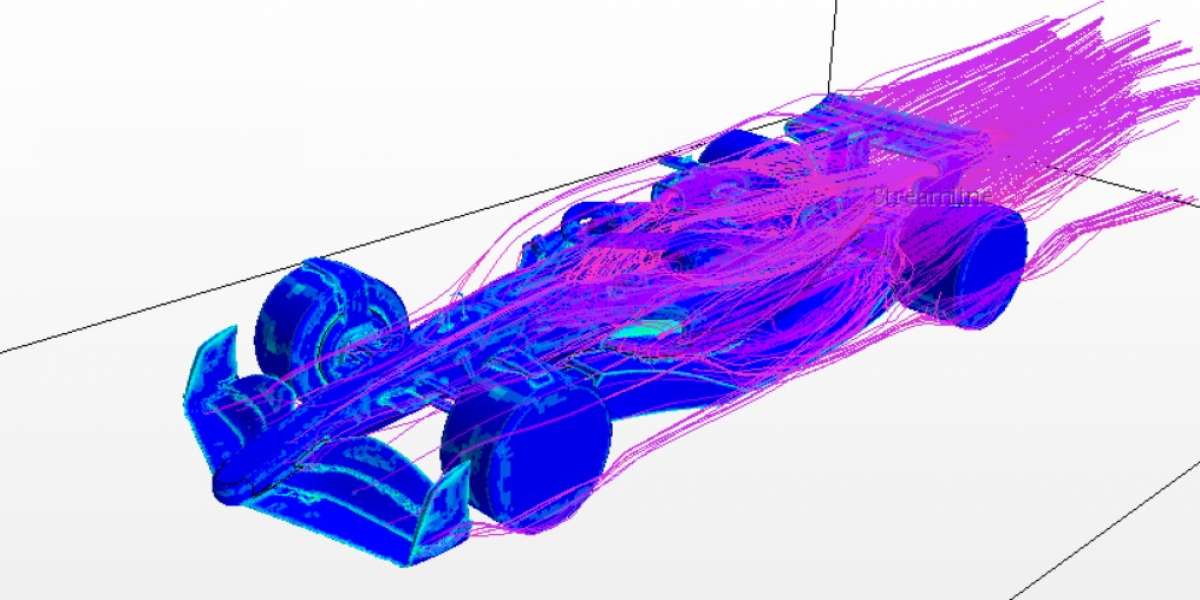

I realized there is a huge opportunity to address all of the customers’ concerns if the testing process could be made less burdensome without compromising reliability. Simulation could be the tool that would enable faster testing without compromising on reliability. Simulation would allow us to perform virtual testing and would reduce the number of prototype versions to one or two instead of five or six in the conventional process. This would take an average of seven months for design-prototype- test iterations. Assuming six people would be used in the test lab, it would take 7 months x 6 people/12=3.5 man years of testing. My estimate was that it would take a month to build a detailed simulation model. I assumed that we will perform six design-simulation iterations and we will need no more than two months after the simulation model is complete. We would only need one simulation engineer for three months to perform simulation. So the total time with simulation path would take 7+ 3= 10 months. The average number of prototypes for two iterations would be 65.

So the net impact of simulation on a product would be reduction of 9.75-3.5 =6.25 man years of testing and the cost of 180-65= 115 prototypes. For this gain, we have to spend 3 months i.e. 0.25 man years of simulation. For simplicity, assume the cost of simulation man years is the same as the testing man years. There is no significant difference in a design engineer’s task. So the net gain would be 6 man years of testing and the cost of 130 prototypes for each product launched. I realized if simulation is implemented, we could more than double the capacity of products by hiring more design engineers and simulation engineers because the test lab was the bottle neck which will address customer requirement #1 i.e. faster launch of products.

I thought if we use simulation, our product would be more reliable because we would have seen stresses, vibrations, fatigue, etc. in the entire range of motion for all of the components. This allows us to address all the failure modes unlike the conventional analysis, where we would go in series in solving one failure mode after another. With the conventional techniques, some of the failure modes are not addressed and happen in the field resulting in unhappy customers affecting the image of the company. So, simulation would satisfy customer requirement #2 i.e. more reliable products.

Simulation allows the engineers to try several concepts. For example, a design engineer creates CAD (Computer Aided Design) models of six design concepts A, B, C, D, E, F and provides them to a simulation engineer. After the simulation engineer runs the simulation, designs C, E F are discarded because they are not able to satisfy one of the load capacity design criteria. So, we do not spend time in building and testing prototypes for C, E F. The other 3 design A, B D seem promising but cannot beat the competition in longevity based on fatigue life simulation. The design engineer will notice the strengths and weaknesses of each design after seeing the simulation results of A, B D. This insight is sufficient for a design engineer to create couple of more design concepts G H which are a combination of strengths of two or more previous designs. Based on simulation, we may find that both design G H satisfies the load capacity criteria, whereas design G is capable of beating the competition, but H is not. So, it would be decided to build prototypes of only design G. It is because of simulation the designer is able to propose design G. Design G is superior to any of the six designs initially proposed and is capable of beating the competition. In addition we will be testing just prototypes of one design G instead of testing prototypes of six designs. This shows how simulation will satisfy customer requirement #3 i.e. significant improvement in existing product.

Therefore, we would more effectively satisfy all the customer requirements if we implemented simulation; however, we would have to hire additional design and simulation engineers which would be a significant cost. I decided that I would train existing design engineers to perform simulation in Stryker Instruments division in 2003. I did this at Stryker Instruments division and as expected my process showed reduction in product development time at Instruments division. Initially, there was lot of resistance to change from the conventional path of testing. People found it hard to believe that simulation can predict close to reality. It took me a year to change the perception of the division by running simulation in parallel to testing and predicting 2-3 weeks in advance when and where the next failure will occur. In 2005, we invested in high-end computers and simulation software. Simulation was implemented in most of the projects in the Instruments division by 2005. In 2006, the Medical division across the street came to know of how simulation was speeding up product development and asked me to help the division in developing simulation infrastructure at Medical division. Later in 2006, I got request from Stryker Development, Stryker Communications, Stryker Endoscopy and Stryker Spine to help their division in implementing simulation. I realized that I did not have enough resources to support the simulation of all the divisions, but I had definitely created a demand for simulation.

Few divisions were using consulting firms at $200-$250/hour to run simulation for them; however, the usage of simulation was very limited. I realized if I could channel this money to support the Finite Element Analysis (FEA) team in India; I could create a center of excellence and address the top three customer concerns for the entire global Stryker at a cost that would be acceptable to the upper management. So, a proposal was made to start a FEA team in India which will allow us to launch innovative reliable products faster. I had proposed the FEA team would charge $60/hour for its services. The proposal was approved by the CEO for two million dollars to have return on investment in two years.

We started the team with six employees. We could not find engineers with experience in medical devices in India, so we hired engineers with automotive experience. I wanted to hire technically talented engineers with knowledge of multidisciplinary fields to address customer demands from different divisions. These engineers should have also proven in their past jobs that they have delivered in tight timelines which was a necessity to compete against existing consulting firms. The future of the FEA team in India depended on these first six employees. The challenge was to find new projects in all the divisions to keep the engineers in India engaged as well as training the new employees in medical devices. I was flying and meeting people in different divisions to sell our simulation services. I realized that it was not sustainable as the demand was increasing. So, I asked a couple of engineers in India to fly to the US and train under me for three months to learn how we get projects from other divisions. In addition, these engineers were also getting exposure to medical device design and simulation, while they were in the US. These engineers would spend some time working on the projects along with other engineers on-site before taking the project to India. The engineers in India would take turns to come to US to work along with me to gain experience in getting projects as well as get exposure to design and simulation of medical devices.

As expected, as simulation started to make the product development process efficient, all the divisions wanted to launch more products which in turn required more design and simulation resources. All the divisions wanted to out-source design work at a lower cost, and we were ready for it. During the first year, we hired sixty people and it was called Stryker India Technical Center. Each division’s product knowledge was different and engineers were taking time in learning when a project was assigned to them. I realized that if we could have dedicated resources for each division; we could make the product development process more efficient because the time lost in the learning curve could be eliminated. A resource dedicated to a division would be considered the extended team of the division. We started offering dedicated resources in design or simulation for 6 months or 1 year on-site or off-site at a cost lower than the hourly rate. This was a huge success resulting in exponential growth. I also learned from experience that it was not efficient to send small simulation or design tasks of less than four hours to team in India. They could be more efficiently executed locally at the divisions, so we would provide on-site resources for such tasks. We started getting requests for software programming, and we expanded our capability to provide that service as well.

Our newly acquired knowledge of business processes were implemented into the business model and the team of 6 employees grew to 500+ employees in 5 years and became a division of Stryker. The Simulation process was made a part of the design control process for the entire Stryker Corporation. It resulted in savings of $135 million per year. The top three customer concerns were addressed. The biggest impact was acceleration of product development. During 2008-2009 when US economy was not in good shape, India Technical Center played a huge role in controlling product development costs. The India Technical Center provides support in design, simulation and programming to all the divisions of Stryker. It also started designing products for the Indian market in 2011. During my ten years at Stryker my team helped in development of 200+ products from concept to launch.